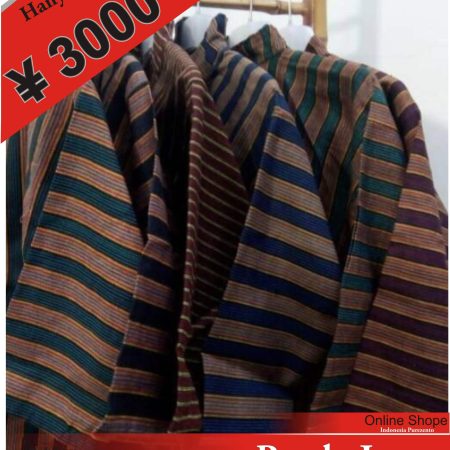

Batik Dobby Cap

Description

Kain Batik Dobby Cap Bahan Dobby Premium dengan menggunakan teknik batik cap yang di buat oleh pembatik propesional kualitas Exsport barang sudah melalui tes QC sehingga sudah di jamin kualitasnya, Bahan batik masih berbau lilin yang mencirikan batik tulis tangan asli. barang yg kami jual masih dalam bentuk kain (belum jahit) motif limited edition. hanya tersedia 1 atau 2 pcs per motif

Deskripsi Produc :

Bahan : Sutra (bertekstur, atbm)

Size : 190 cm x 115 cm atau 200 cm x 110 cm

DIJAMIN ASLI BATIK TULIS/HANDMADE PEKALONGAN

Ada banyak motif batik silahkan hubungi kami untuk motif yang lain.

HARGA SUDAH TERMASUK ONGKIR se-JEPANG

There are no question found.

General Inquiries

There are no inquiries yet.